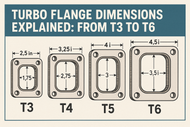

Turbo Flange Dimensions Explained: From T3 to T6

Posted by SS Auto Chrome on 8th Jul 2025

Even though turbochargers make engines more powerful, they only fit on certain engines because of a small but important part called the turbo flange. Connects the turbo to the downpipe or exhaust. It's important to get the right size because the wrong one can cause leaks, bad performance or even damage.

We'll explain the various turbo flange dimensions in this post, break them down into the most popular types T3 to T6, and show you how to pick the best one.

Why Turbo Flange Size Matters?

Every turbo flange comes in a different shape, bolt layout, and port size. These differences affect how the turbo fits, how exhaust flows, and how much power your setup can handle. Picking the wrong size could slow performance or create exhaust leaks.

Turbo flanges come in different sizes, with T3, T4, T5, and T6 being some of the well-known options used to match different turbo and engine setups. There are different measurements for each of these that work with different engine bays and power levels.

Common Types of Turbo Flanges

Many types of turbo flanges exist, but the most popular ones are T3, T4, T5, and T6. These names refer to a size range and bolt pattern that many turbos follow.

Let’s take a closer look at each.

T3 Turbo Flange

The T3 turbo flange is one of the most popular choices for street and light performance builds. It has a compact size, which makes it easy to install in tight engine bays.

Typical T3 turbo flange dimensions:

- Bolt hole spacing: ~2.5” x 1.75”

- Port opening: ~1.75” x 1.38”

T3 flanges are great for smaller engines or lower boost setups. If you’re aiming for quick spooling and decent power, this is a reliable choice.

T4 Turbo Flange

A step up from T3 is the T4 turbo flange. This one is larger and supports more airflow, making it good for higher horsepower builds.

Typical T4 turbo flange dimensions:

- Bolt hole spacing: ~3.25” x 2.75”

- Port opening: ~2.5” x 2.0”

T4 turbo flange dimensions are built wide to let in more airflow, making them fit for handling bigger turbos. In T3 T4 downpipe flange, T4 might be better than a T3 if you're making a race car or a high-boost street car.

T5 and T6 Turbo Flanges

T5 and T6 flanges are designed for very large turbos. These are often found on drag cars or heavy-duty racing applications.

T5 turbo flange (sometimes called T04 flange) dimensions:

- Bolt hole spacing: ~3.75” x 2.75”

- Port opening: varies depending on turbo

T6 is the biggest flange size among these options. It allows maximum flow and supports very high horsepower.

Typical T6 turbo flange dimensions:

- Bolt hole spacing: ~4.25” x 3.5”

- Port opening: ~3.0” x 2.75”

Due to their size, these flanges require more space and stronger supporting parts. They’re not usually used in daily-driven vehicles.

Divided vs. Open Flanges

You should know whether you need an open, or split turbo flange when looking for one.

- Open flanges: A single port where all of the exhaust gases flow into the turbo at the same time.

- Divided flanges: Two separate ports that help split exhaust pulses, improving spool, and efficiency in twin-scroll turbo systems.

Both types exist in all size categories (T3 through T6), so make sure you pick the right kind for your setup.

Adapting Between Different Turbo Flanges

Sometimes, you may have a turbo with one type of flange turbo, but your manifold or downpipe has another. That's why flange spacers are useful. You can connect plates that don't match with these adapters without having to cut or weld.

However, be careful when using adapters. They can affect how the turbo sits and may change how the exhaust flows. Always check clearance and flow direction.

Which Turbo Flange Is Best for Your Build?

With so many different turbo flanges available, how do you pick the right one? Here are some simple tips:

- Know your horsepower goals.

When you need more power, you generally need bigger turbos, which need bigger flanges like T4 or T6. - Check available space.

Large flanges are not always possible in engine bays. T3 is small, but T6 needs more space. - Match the manifold and turbo.

A turbo and a manifold should have the same size and type of flange (open or divided). - Think about spool time.

It's faster to spin with smaller flanges (T3), but the top-end power may be less. It takes longer to spool larger valves (T4 and T6), but they can handle more flow. - Stick to proven setups.

If you're unsure, look at builds similar to yours and copy what works.

A Closer Look at T4 Turbo Flange Dimensions

Here are the T4 turbo flange dimensions again, since T4 is a popular size for performance builds.

A standard T4 flange typically has:

- 4 bolt holes in a rectangular pattern

- Center-to-center bolt spacing: ~3.25” horizontally and ~2.75” vertically

- Port size: around 2.5” x 2.0”

T4 flanges come in open or divided versions. The flange shape should match the shape of turbo and manifold setup.

How to Measure Turbo Flange Dimensions?

Many people think the turbo flange is a small part, but it is very important to the way your turbo works.

- Measure bolt hole spacing

Use a caliper or ruler to measure from the center of one bolt hole to the next. - Measure the port opening

Measure the inside opening of the flange. This shows how much exhaust can flow into the turbo. - Check the shape

Tell what shape it is rectangle, oval, or something else. Air moves differently depending on the shape. - Look for markings

Some flanges have numbers or names stamped on them. These can help identify the type.

Many people think the flange turbo is a small part, but it is very important to the way your turbo works. Whether you're using a T3, stepping up to T4, or going big with T6, understanding turbo flange dimensions can help you make smarter choices. Always make sure your turbo, manifold, and other parts fit together properly. Knowing the different turbo flanges out there will save time, effort, and money as you plan your build.